Description

- Water Inlet & Outlet (NPT): 1/2″

- Cooling Capacity: 1.1 tons | 12,966 BTU/H

- Total Installed Power: 2.1 kW

- Water Pump: 0.5 HP

- Tank Capacity: 6 Gal

Power Info

Water Inlet & Outlet (NPT): 1/2″

Cooling Capacity (1): 1.1 tons | 12,966 BTU/H

Total Installed Power (2): 2.1 kW

Water Pump: 0.5 HP

Tank Capacity: 6 Gal

Specifications

Power Supply (voltage/phase): 230V/1Ph/60Hz

Refrigerant Type: R410A

Inlet Water Temperature (minimum): 32°F

Inlet Water Temperature (maximum): 86°F

Oulet Water Temperature (minimum): 32°F

Oulet Water Temperature (maximum): 68°F

Ambient Temperature (minimum): 23°F

Ambient Temperature (maximum): 108°F

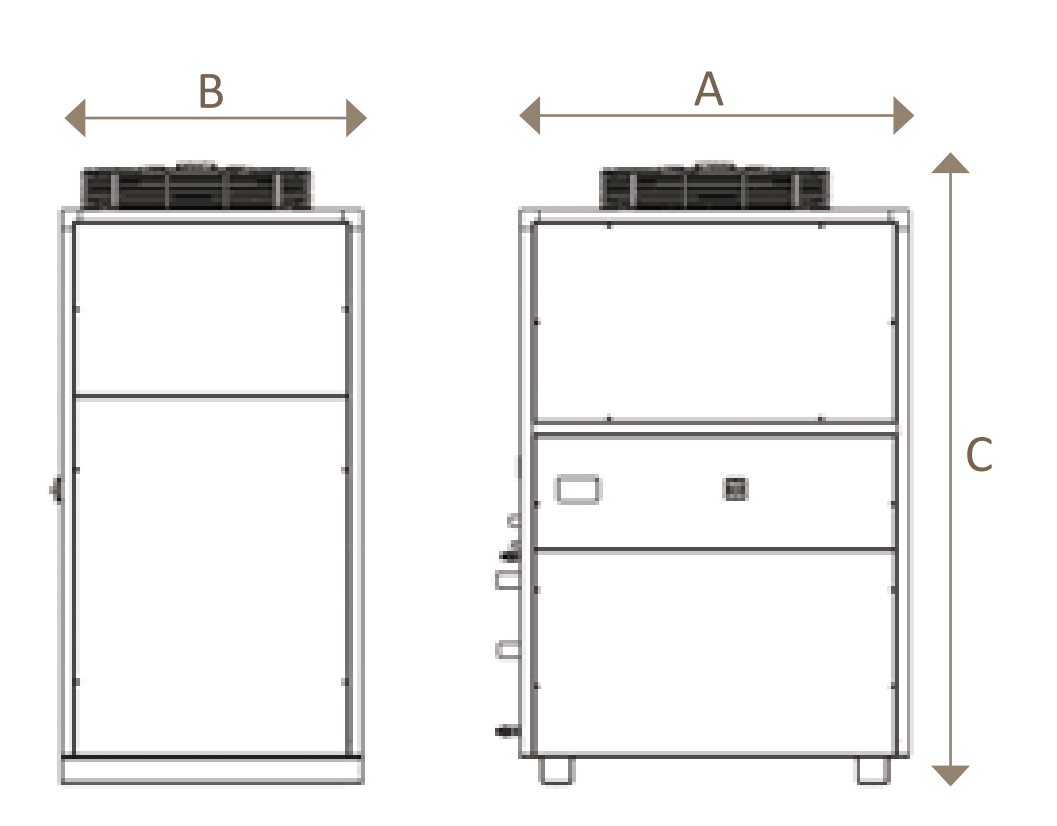

Dimensions

Length: 29 in

Width: 22 in

Height: 35 in

Approx. Weight: 220 lbs

Correction Factors (4)

| Water Outlet Temperature (°F) | 30 | 35 | 40 | 45 | 50 | 55 | 60+ |

| Correction Factor | 0.68 | 0.79 | 0.91 | 1 | 1.1 | 1.19 | 1.27 |

| Ambient Temperature (°F) | 75 | 80 | 85 | 90 | 95 | 100 | 105 |

| Correction Factor | 1.18 | 1.14 | 1.11 | 1.04 | 1 | 0.96 | 0.92 |

| Evaporator ∆T (°F) (5) | 7 | 9 | 10 | 12 | 14 | 16 | 18 |

| Correction Factor | 0.993 | 1 | 1.003 | 1.009 | 1.015 | 1.021 | 1.025 |

| Condenser ∆T (°F) (6) | 10 | 12.5 | 15 | 17.5 | 20 | 22.5 | 25 |

| Correction Factor | 1 | 0.99 | 0.98 | 0.97 | 0.96 | 0.95 | 0.93 |

| Ethylene Glycol (%) | 0 | 10 | 20 | 30 | 40 | 45 | 50 |

| Correction Factor | 1 | 0.99 | 0.98 | 0.97 | 0.96 | 0.95 | 0.93 |

Notes:

(1) Assumes 45°F cooling water supply, 55°F cooling water return and 95°F, ambient temperature. For all other conditions refer to the correction factors.

(2) Total nominal absorbed power by (all) compressor(s) at rated inlet conditions using 230/1/60 or 460/3/60 power supply as applicable.

(3) All models are 60 Hz.

(4) To be used as a guide only. All applications should be confirmed by CTA.

(5) Assumes no change to condenser inlet water temperature.

(6) Assumes no change to evaporator outlet water temperature.

- Standard water temperature control is +/- 3°F. Close temperature control is available.

- Crankcase heater included as standard.

EXCHANGER: The OPTIFLUX exchanger, patented by CTA group, developed in partnership with Alfa Laval, the world leader in exchangers. The tube in flexible shell heat exchanger is integral to the buffer vessel and protects against damage which can occur with improper setup or maintenance.

BODY: It is made up of a frame in aluminum sections and panels in PVC plastic coated galvanized steel all mounted on a steel frame, epoxy paint. Option: aluminum or stainless steel panels.

FAN WITH STREAMLINED BLADES AND AIR-COOLED CONDENSER: Units are fitted with an axial cooling fan with balanced aluminum blades and an air-cooled condenser in copper pipes and aluminum vanes. This feature reduces noise levels and improves ventilation air flow.

SCROLL COMPRESSOR: IP features Copeland Scroll compressors as standard on models IP15 to 1502US. Scrolls minimize power consumption, noise, vibration and moving parts while maximizing reliability and resistance to liquid refrigerant returns.

HYDRAULIC KIT: It is made up of a generously sized storage tank, avoiding the risk of compressor short cycles, and a centrifugal pump as standard on all sizes, with a pressure gauge and pressure differential cut-out on the water circuit. An adjustable by-pass valve allows the pressure of the water supply flowing out of the unit to be regulated.

CAREL REGULATION: Operation is controlled by miroprocessor according to the starting temperature of the water, monitored by sensors. The digital interface continuously indicates the water outlet temperature. It also displays the operating instructions and the various adjustment parameters.

REAR VENTILATION GRILLE

ACCESSORIES:

- Rubber anti-vibration mountings (supplied loose)

- Modulating fan speed condensing control

- Fan speed control

- Crankcase heater

- Remote control

- Sequence phase relay

- Refrigerant gauges (standard on models IP251US and above)

- Electromechanical flow switch