What is a chiller?

Industrial chillers are used for controlled cooling of products, mechanisms and machinery in a variety of industries. A chiller removes heat from the process water and transfers it to air via a heat exchange process.

Using a mechanical compressor and the wonders of the refrigeration cycle, water chillers are able to cool the water to below ambient temperature. Water chiller capacities are commonly measured in tons and BTU/hr of cooling.

Pro Tip: Always check the ambient temperature and other factors such as setpoint temperature that were assumed when the chiller’s rated (advertised) capacity was established. At high ambient temperatures or low setpoint temperatures a chiller won’t be able to move as much heat. So a two ton chiller rated at a favorable set of conditions is not able to do as much as a two ton rated at a less favorable set of conditions. Make sure you are comparing apples to apples.

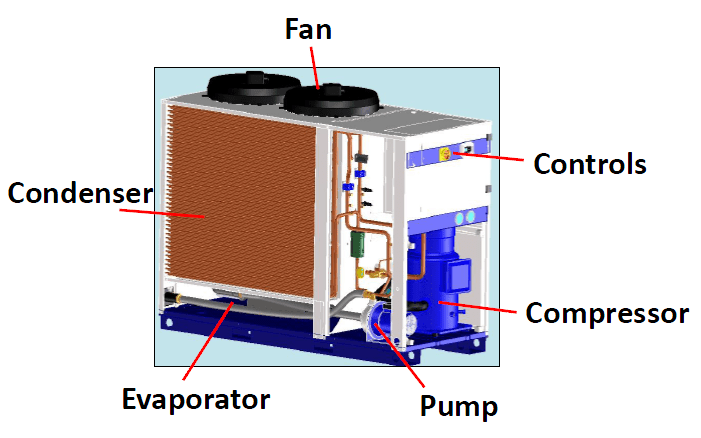

General parts of a self-contained recirculating water chiller

How does a chiller work?

Cooled water is drawn from the tank, pumped from the chiller out to the process where it is warmed, and then returned through the chiller’s evaporator and back into the tank. An adjustable thermostat senses the liquid temperature, cycling the compressor on the chiller to maintain a constant temperature in the tank. The water flows from the chiller to the application’s point of use and back.

Having a contaminant free “closed loop” system will increase your chiller’s efficiency and lengthen its life. A closed-loop industrial chiller recirculates clean coolant or clean water (sometimes with conditioning additives) at a constant temperature and pressure to increase the consistent and repeatable variables.

Will you need an external heat exchanger?

If your end use is to cool oil in a piece of machinery, or supply cooled, clean potable water to a bakery process, your chiller is probably going to be hooked up to an external heat exchanger. This means you can keep the same water passing through the chiller in a loop. The heat exchanger will do the heat transfer with your end-use material and the two will never actually mix. This method is usually less expensive than getting a food grade chiller or one that is designed to directly circulate oil.